A Comparison of Mortar and Silicone Glass Block Windows

Milwaukee Glass Block chooses to use mortar to build our glass block windows because of its tested benefits and ability to withstand decades of exposure to the elements.

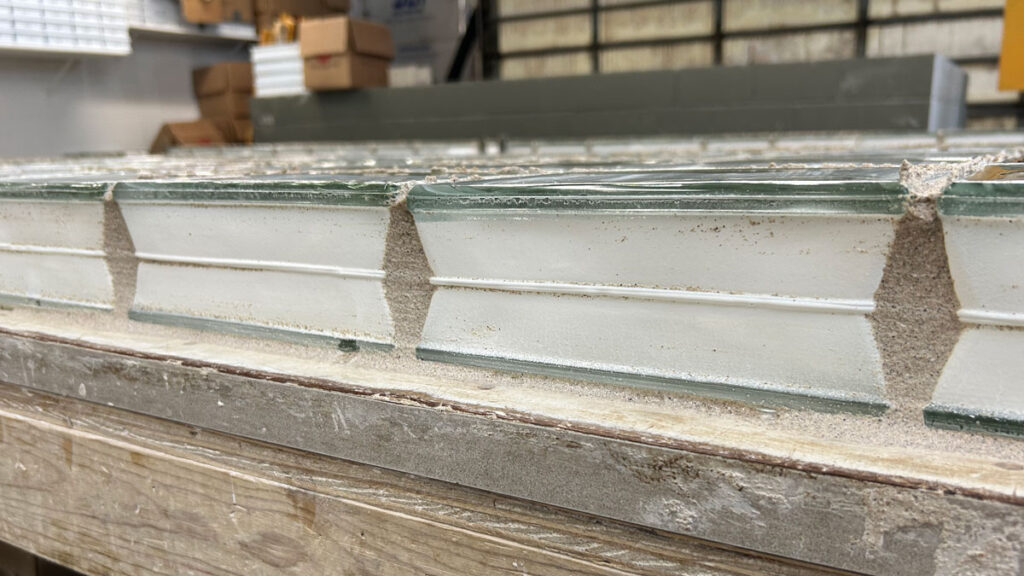

Silicone and Mortar Glass Block Window Joints Compared

Silicone-built glass block windows are glued together on their edges, leaving a hollow joint cavity between the blocks that is susceptible to mold, mildew and algae growth once the silicone joints fail

Mortar-built glass block windows have a through-joint filled with mortar similar to a brick wall, meaning they are completely solid cement from front to back with no gaps or empty cavities

Disadvantages of Silicone Window Installations

Mortar Glass Block Windows

- Glass blocks are engineered for masonry (mortar) application, not silicone (International Building Code Section 2103).

- Front-to-back mortar joints provide superior strength and durability and accommodate the natural expansion and contraction of the blocks, which prevents mold, condensation, and other impurities from penetrating the window structure. .

- Front-to-back mortar joints provide superior security and are far more impenetrable than silicon joints

- Mortar has been used in glass block applications for over a century.

Silicone Glass Block Windows

- The use of silicone in glass block applications is not up to code (International Building Section 2103).

- Silicone glass block windows generally fail to meet building codes

- Do not have front-to-back joints, meaning the glue is on the outside and inside edges, creating an empty cavity between the blocks.

- Silicone does not effectively accommodate the expansion and contraction of the blocks and will loosen over time.

- Silicone can be cut with something as simple as a utility knife.

- Silicone windows are susceptible to mold, mildew, and condensation forming between the blocks as they age, similar to how caulking around a bathroom tub degrades over time.

- Typically, silicone is used because it is inexpensive and fast, which sacrifices quality.